Biodeterioration has been defined as "any undesirable change in the properties of a material caused by the vital activities of organisms" (H. J. Hueck). This article will be concerned with the deterioration of textile materials caused by micro-organisms such as fungi and bacteria, and the steps that can be taken to prevent or minimize their effects.

Not all breakdown of materials by micro-organisms is undesirable. When we discard objects that we have finished with, we expect "Nature" to clear away what has then become refuse. Such degradation is an essential process in the maintenance of the world in which we live, and a means of recycling many of the essential elements contained in these materials. However, when it is an unwanted process, as occurs when textiles are affected by rot or mildew, then it can be a serious problem to manufacturers and users alike.

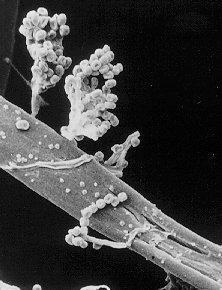

Under suitable conditions micro-organisms which inhabit soil, water, and air can develop and proliferate on textile materials. These organisms include species of microfungi, bacteria, actinomycetes (filamentous bacteria), and algae. Textiles made from natural fibres are generally more susceptible to biodeterioration than are the synthetic man-made fibres. Products such as starch, protein derivatives, fats, and oils used in the finishing of textiles can also promote microbial growth. Micro-organisms may attack the entire substrate, i.e. the textile fibres, or they may attack only one component of the substrate, such as plasticizers contained therein, or grow on dirt that has accumulated on the surface of a product. Nevertheless, even mild surface growth can make a fabric look unattractive by the appearance of unwanted pigmentation. Heavy infestation which results in rotting and breakdown of the fibres and subsequent physical changes such as a loss of strength or flexibility may cause the fabric to fail in service. The material is attacked chemically by the action of extracellular enzymes produced by the micro-organism for the purpose of obtaining food. However, microbial activity can be minimized by keeping susceptible materials dry, as surface growth will only occur when the relative humidity is high. Therefore, some form of chemical protection is normally only required with textiles likely to be used in adverse conditions under which they remain wet or damp for long periods of time.

Natural fibres

Plant fibres such as cotton, flax (linen), jute and hemp are very susceptible to attack by cellulolytic (cellulose- digesting) fungi. Indeed, the complete degradation of cellulose can be effected by enzymes, produced by the fungi and known as cellulases. Diagram 1 explains the chemical process concerned. The spores of these microfungi are present in the atmosphere and when they settle on suitable substrates they can quickly grow under favourable conditions of temperature and humidity. The characteristic growth form of these "mould" fungi is known as mildew, a superficial growth which may discolour and stain the fabric, as many microfungi are capable of producing pigments. The best protection against mildew is to make certain that the fabrics are dry when stored and that they do not become damp during storage. Fabrics which are to be used out of doors for awnings, beach umbrellas, military uniforms, sails, tarpaulins, tents, truck and boat covers, shoes and shoe linings, are treated with a fungicidal finish to protect them from mildew damage and rotting. Algal greening may also occur on fabrics which remain wet for long periods and can cause particular problems in the tropics.

Plant fibres such as cotton, flax (linen), jute and hemp are very susceptible to attack by cellulolytic (cellulose- digesting) fungi. Indeed, the complete degradation of cellulose can be effected by enzymes, produced by the fungi and known as cellulases. Diagram 1 explains the chemical process concerned. The spores of these microfungi are present in the atmosphere and when they settle on suitable substrates they can quickly grow under favourable conditions of temperature and humidity. The characteristic growth form of these "mould" fungi is known as mildew, a superficial growth which may discolour and stain the fabric, as many microfungi are capable of producing pigments. The best protection against mildew is to make certain that the fabrics are dry when stored and that they do not become damp during storage. Fabrics which are to be used out of doors for awnings, beach umbrellas, military uniforms, sails, tarpaulins, tents, truck and boat covers, shoes and shoe linings, are treated with a fungicidal finish to protect them from mildew damage and rotting. Algal greening may also occur on fabrics which remain wet for long periods and can cause particular problems in the tropics.

Animal fibres are more resistant to mildew growth than plant fibres. Pure silk is less susceptible if completely degummed. Wool decays only slowly but chemical and mechanical damage during processing can increase its susceptibility to biodeterioration. When stored under very adverse conditions wool will eventually rot by the action of the proteolytic (protein-digesting) enzymes secreted by many microfungi and bacteria.

Diagram 1: How cellulose is broken down under the influence of an enzyme. The diagram illustrates cleavage of a "glycosidic" bond in cellulose (a polymer of glucose) by reaction with a molecule of water. This hydrolysis, the fundamental step in the biodegradation of cellulose, which would otherwise be immeasurably slow, is accelerated by the presence of an "enzyme", or biocatalyst. The insoluble polymer is converted into soluble sugars which can then be metabolized inside the bacterial or fungal cells.

Man-made fibres

Man-made fibres derived from cellulose are susceptible to microbial deterioration. Viscose (rayon) is readily attacked by mildew and bacteria; acetate and triacetate are more resistant although discoloration can occur if the fabrics are incorrectly stored. Fibres made from synthetic polymers (e.g. acrylic, nylon, polyester, polyethylene, and polypropylene fibres) are very resistant to attack by micro-organisms. The hydrophobic nature of these polymers is probably an important factor determining their resistance. Also, these synthetic polymers contain chemical bonds which do not occur or are uncommon in nature, and so perhaps they have not been around long enough for micro-organisms to evolve the appropriate enzymes necessary to initiate their breakdown. Although the substance of a synthetic fibre by itself will not support microbial growth, contaminants of low molecular weight (e.g. residual traces of the caprolactam monomer of nylon 6) and compounds such as lubricants and spinning oils used in the finishing of textiles may provide sufficient nutrient for mild surface growth of a micro-organism. In most cases this will not affect the strength of the fabric but can give rise to staining and discolouration which are often difficult or impossible to remove.

Plastics

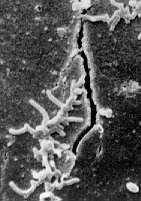

Several types of plastic materials have become important as components of textile products, for example, to provide waterproof coatings for rainwear. Plastics which are made mainly or entirely from polymers such as polyethylene are usually highly resistant to microbial growth. However, two types of plastic used extensively as coatings for textile materials, plasticized polyvinyl chloride (PVC) and polyurethanes, are susceptible to biodeterioration. In the case of PVC, the polymer itself does not readily provide a source of nutrients for bacteria and fungi. The susceptibility of PVC formulations to microbial attack is related to the amount and types of plasticizers, fillers, pigments, and stabilizers, etc., added during processing. Many of these additives are organic compounds of relatively low molecular weight. For example, plasticizers (predominantly esters of organic acids, polyesters, and chlorinated hydrocarbons), which are added to increase the flexibility of an otherwise brittle polymer, will in most cases support microbial growth and their degree of susceptibility exercises a profound influence on the propensity of the textile coating to biodeterioration; such microbial utilization of the plasticizers may cause the PVC coating to crack during use. With polyurethanes on the other hand the actual polymer is capable of supporting microbial growth because of the similarity of some of the chemical linkages in polyurethanes to those found in nature. As a practical measure, therefore, biocides are often added to both plasticized PVC and polyurethanes.

Several types of plastic materials have become important as components of textile products, for example, to provide waterproof coatings for rainwear. Plastics which are made mainly or entirely from polymers such as polyethylene are usually highly resistant to microbial growth. However, two types of plastic used extensively as coatings for textile materials, plasticized polyvinyl chloride (PVC) and polyurethanes, are susceptible to biodeterioration. In the case of PVC, the polymer itself does not readily provide a source of nutrients for bacteria and fungi. The susceptibility of PVC formulations to microbial attack is related to the amount and types of plasticizers, fillers, pigments, and stabilizers, etc., added during processing. Many of these additives are organic compounds of relatively low molecular weight. For example, plasticizers (predominantly esters of organic acids, polyesters, and chlorinated hydrocarbons), which are added to increase the flexibility of an otherwise brittle polymer, will in most cases support microbial growth and their degree of susceptibility exercises a profound influence on the propensity of the textile coating to biodeterioration; such microbial utilization of the plasticizers may cause the PVC coating to crack during use. With polyurethanes on the other hand the actual polymer is capable of supporting microbial growth because of the similarity of some of the chemical linkages in polyurethanes to those found in nature. As a practical measure, therefore, biocides are often added to both plasticized PVC and polyurethanes.

Use of biocides

The best method of avoiding microbial deterioration is to use synthetic materials which are inherently resistant to attack. An alternative strategy is to apply antimicrobial chemicals known as "biocides" which are normally incorporated into the finished textile product. So far no preservative agent has been discovered which gives complete protection nor which is without some disadvantage. The requirements for an "ideal" biocide include:

1. Effective against a wide range of micro-organisms, particularly bacteria and microfungi.

2. Active during the life of the product.

3. Of low mammalian toxicity and non-toxic to humans at the concentrations used.

4. Colourless and odourless.

5. Effective at low concentrations.

6. Inexpensive and easy to apply.

7. Resistant to sunlight and leaching from the fabric.

8. Not affecting fabric handle or strength.

9. Compatible with water-repellent and flame-retardant agents, dyes, and other textile auxiliaries.

10. Does not sensitize the fabric to damage by light or other influences.

Needless to say, the ideal biocide is not yet available and the "compromise" selection of a suitable product is not always easy. Some chemicals, for example organo-mercury compounds, have fallen out of favour because of their persistent and cumulative toxic effects in the environment. Textile materials which are to be used outdoors require a stable fungicide that is resistant to being washed out by rainwater and to breakdown by light. If the environment is extremely wet, control of algae and bacteria becomes more important. However, many compounds which are effective against microfungi are not necessarily good bacteriocides and vice versa.

Commonly used biocides in the textile industry include organo-copper compounds, organo-tin compounds, and chlorinated phenols. These act by interfering with the energy-producing processes of microbial cells. Copper naphthenate and copper-8-hydroxyquinolinate are extremely versatile biocides, very effective against fungi, bacteria, and algae. They are applied in particular to protect textiles likely to be exposed to soil and to severe weathering conditions, e.g. cotton and flax canvases, awnings, tarpaulins, cordage, ropes, sacks, tents, military uniforms and military equipment. The main disadvantage is that they impart a yellow-green colour to treated materials. Pentachlorophenol esters, typically pentachlorophenyl laurate (LPCP), are resistant to leaching by rainwater and so are used as fungicides for the rotproofing of a wide range of textiles including cotton, flax, and jute fabrics used as covers, tarpaulins, shop blinds, tents, etc.; also carpet backings, coated fabrics, hospital materials, mattress covers, pressed felts and woollen textiles. Some biocides can serve more than one purpose; thus organo-tin compounds can serve as stabilizers for plastic formulations as well as fungicides.

Application of biocides to textile fabrics for rot-and mildew-proofing is usually carried out as a final finishing process. The fabric is impregnated with either a solvent (usually white spirit) solution or, more usually, an emulsion of the biocide; it is then mangled and dried using a cylinder dryer, a stenter, or other suitable equipment. The fabric may be scoured first but more usually, and especially with heavyweight materials, the biocides are applied to loomstate material without scouring. Often they are co-applied with water-repellents, fire-retardants, and pigments. In vinyl polymers such as PVC the biocide is normally dispersed in the plasticizer which is usually the most biodegradable component. As the surface film is removed, fresh plasticizer will migrate to the surface, carrying with it a constant source of biocide. However, these products ultimately lose their protective qualities through weathering even though 70%-80% of the biocide remains chemically unchanged in the formulation. One possible reason for this is that, under the effects of heat and ultraviolet radiation, depolymerization of the vinyl resin and subsequent cross-linkage may encapsulate the biocide, preventing its migration to the surface where biodeterioration takes place.

Biocides are also used to provide hygienic finishes for fabrics that will be used in health-care products. These finishes are classified as either renewable or durable, although even durable finishes are removed gradually during laundering. Renewable finishes can be replaced during laundering, for example quaternary ammonium compounds used to combat napkin rash. Some protection against the microfungi responsible for athlete's foot is also claimed for hygienic finishes that are applied to socks and linings for footwear.

Conclusion

Quantifying the extent of biodeterioration of textile materials is difficult but it must be measured in terms of millions of pounds sterling annually in the UK alone. Failure of materials can often be a complex phenomenon resulting from a combination of chemical, physical, and microbiological causes. The problem is most serious with fabrics used outdoors but other products such as floor coverings, rug backings, shower curtains, vinyl baby pants, and mattresses may also require an antimicrobial finish to control fungal and bacterial surface growth. Where possible, materials inherently resistant to microbial attack should be selected rather than materials which require protection. Thus, synthetics which resist mildew compete favourably with cotton in making sails for boats or shower curtains. Further research is required into ways of making both natural and synthetic materials more resistant to biodeterioration by chemical modification of their structure, particularly since doubts have now been raised about the toxicity and environmental persistence of some of the hitherto well established biocides. It is also to be expected that improved biocides will appear on the market to meet new regulations brought in by governments concerned about the environmental impact of existing compounds.